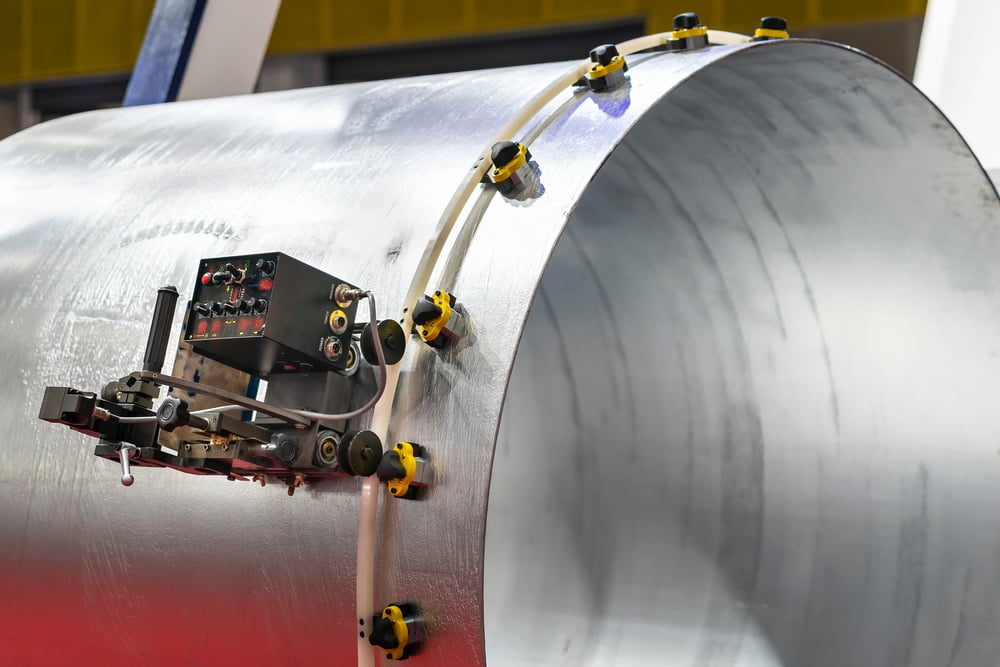

When it comes to pipe cutters, there are a few different types on the market. You’ve probably heard of, or even used, electric and manual pipe cutters. But have you heard of pneumatic pipe cutters?

Pneumatic pipe cutters are a specific type of pipe cutter that uses air pressure to cut through pipes. And unlike electric and manual pipe cutters, pneumatic pipe cutters don’t rely on electricity or personnel. Instead, they use a simple air compressor to get the job done.

So, why should you consider using a pneumatic pipe cutter? Below are six reasons why you may need one:

- Increased Speed

Think about it: every minute counts on the job site. That’s why a pneumatic pipe cutter is such an essential tool. It can help you quickly and easily cut through pipes, reducing the time you spend cutting them.

That’s because it doesn’t require manual labor—you simply press a button, and the cutter does the rest. It also eliminates the need for blades, meaning there’s no danger of nicking or damaging the pipe. Plus, there are no sparks or heat, so you don’t have to worry about accidents related to such.

- Enhanced Accuracy

It’s hard to be precise when cutting metal pipes manually with a hacksaw or coping saw. There’s always some guesswork involved, and it’s easy to make a mistake. On the other hand, with a pneumatic pipe cutter, you’re guaranteed accurate cuts every time.

The cutter head is mounted on a precision guide rail, so the pipe is automatically centered during the cut. It results in clean cuts that are exactly the right size and shape. There’s no room for error, so you can be confident that your pipes will fit perfectly every time.

- Leaves The Pipe Undamaged

One of the notable advantages of using a pneumatic pipe cutter, whether starting a project from scratch or working on renovations, is that it doesn’t damage the pipe. Unlike other methods of cutting a pipe, which can crush or dent it, a pneumatic pipe cutter cleanly slices through the pipe without leaving any marks. That means the pipe can be easily reconnected after it’s been cut. It’s that seamless!

This pipe-cutting method not only prevent damage to the pipe but also makes the job much easier. There’s no need to worry about having to fix anything after you’ve finished cutting the pipe. It also means that you can be more precise with your cuts, ensuring that your pipe cuts are exactly how you want them to be.

- Improved Safety

When working with a pneumatic pipe cutter, you won’t have to worry about flying debris like you would with a manual cutter. That’s because the cutting action is contained within the head of the tool.

And because the cutting head is enclosed, there’s also less of a chance that you’ll accidentally cut yourself. In fact, many pneumatic pipe cutters come with a guard that completely covers the blade when it’s not in use, keeping everyone extra safe.

- More Comfortable To Use

Pneumatic pipe cutters are typically lighter and more compact than their electric counterparts, which makes them easier to use in tight spaces. But that’s not the only advantage they bring in terms of comfort.

With a pneumatic pipe cutter, you don’t have to put in as much force because the machine does most of the work for you. It means that you won’t get as tired, and your arms won’t feel as sore at the end of the day.

Another benefit is that you can adjust the pressure on the cutter to suit your needs. So, if you’re working with a particularly tough piece of pipe, you can increase the pressure and get the job done quicker.

- Can Cut Multiple Materials

Pneumatic pipe cutters are versatile and convenient tools. Not only can it cut on polyvinyl chloride (PVC), but it can also cut through chlorinated polyvinyl chloride (CPVC), polyethylene (PE), rubber hose, and cross-linked polyethylene (PEX). So if you’re working on a project that involves multiple types of pipes, a pneumatic cutter is a great option. Instead of lugging around various saws or cutters for each type of material, you can just use one pneumatic cutter for everything.

Conclusion

As you can see, pneumatic pipe cutters offer more advantages than other types of pipe cutters. They are easier to use, more precise, and versatile. If you’re looking for a pipe cutter that could make your job easier, consider using a pneumatic pipe cutter.